How to Soundproof a Room: A Comprehensive Guide to Soundproofing Materials

In an increasingly noisy world, the peace and quiet offered by a soundproof room has become a prized possession. Yet, many people still wonder, “How to soundproof a room effectively?” In this guide, we address this question by examining the scientific and material advancements in soundproofing.

What is Soundproofing and How to Soundproof a Room Effectively?

At its core, soundproofing aims to diminish the sound pressure between a noise source and its receiver. Whether you want to keep sound in or keep it out, the methodology remains the same, making its application versatile.

Deciphering STC, IIC, and NRC Ratings

When considering how to sound proof a room, it’s vital to understand the metrics that measure effectiveness. Sound Transmission Class (STC) gauges how well airborne sound is blocked, Impact Insulation Class (IIC) assesses impact noise insulation, and Noise Reduction Coefficient (NRC Rating) measures a material’s sound absorption. Familiarizing yourself with these ratings will help you better understand how to sound proof a room to meet your needs.

Choosing the Right Soundproofing Materials

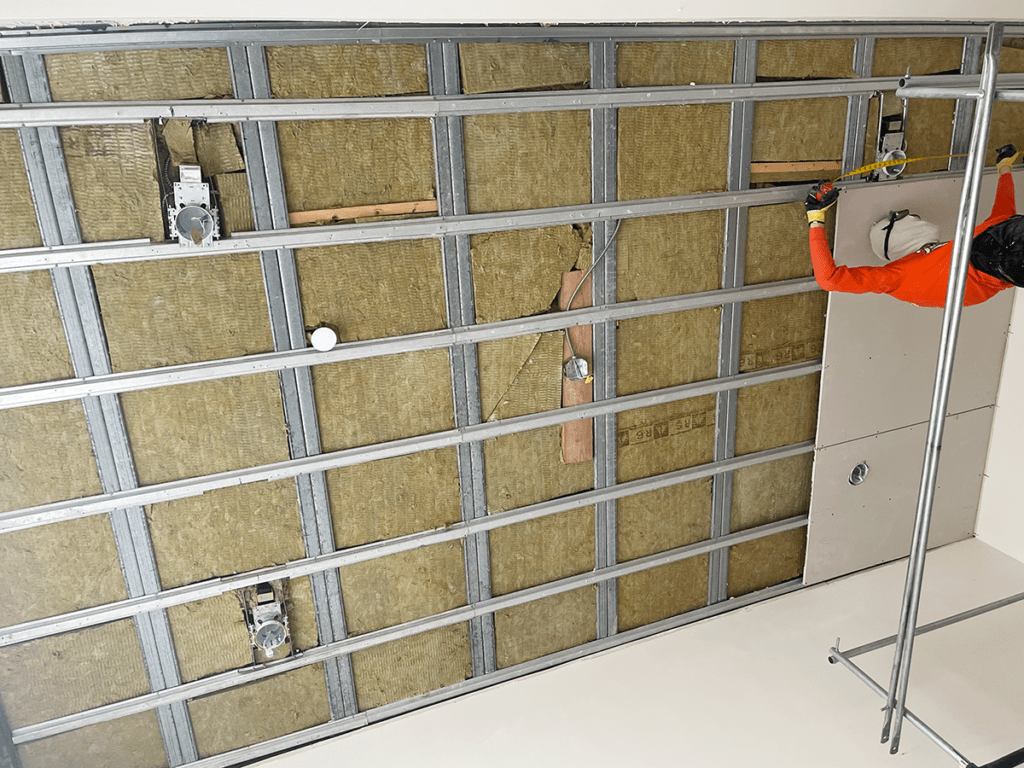

Quality and type of materials are crucial in determining how successful your soundproofing will be. Mass Loaded Vinyl (MLV), known for its sound-blocking abilities, is a popular choice and a Hush Soundproofing go to. Soundproof drywall, especially when used in conjunction with sound-damping sheets or spray foam, offers another effective alternative.

The Power of Decoupling

In the realm of expert advice on how to soundproof a room, decoupling is often mentioned as a highly effective technique. It involves separating two surfaces of a wall to create an air gap, drastically reducing the paths along which sound can travel. Most ceiling impact noise reduction treatments use resilient isolation clips with hat channel. In essence, it’s like constructing an acoustic ‘force field.’

Geographical Variabilities

Soundproofing isn’t a one-size-fits-all solution. While understanding how to sound proof a room is universal, the effectiveness of methods can vary based on factors like exterior noise levels, types of construction materials, and even regional legislation.

The Best Soundproofing Materials for Mastering How to Soundproof a Room

As you navigate the complex world of soundproofing, your choice of materials can make or break your efforts. Here, we break down the top 10 soundproofing materials to consider for your project:

- Soundproof Insulation: Mineral Wool, Rockwool, Owens Corning

- Mass Loaded Vinyl (MLV): Vynaflex, Sonic-Shield

- Soundproof Drywall: Quietrock, Soundbreak XP

- Viscoelastic Compound: Green Glue, Noxudol

- Resilient Isolation Channel: Kinetics, Studco

- Resilient Isolation Clips: Pac, Resilmount

- Sound Damping Sheets: Acoustiblock, Megasorber

- Acoustical Caulk: OSI, Manus

- Spray Foam: Foam it Green, Great Stuff

- Acoustic Foam: Auralex, Sonex

With these materials at your disposal, learning how to sound proof a room becomes a task rooted more in precision than in guesswork.

Six Key Elements of How to Soundproof a Room: Adding “Sealing” to the Mix

Soundproofing can be understood through six main elements, each crucial in their unique way. The previous section touched on five of them: Absorption, Damping, Decoupling, Distance, and Mass. Here, we introduce the sixth element—Sealing.

- Absorption: This is about reducing resonating frequencies within a cavity like a wall or ceiling. Materials such as Rockwool and Open Cell Foam are commonly used. Acoustic Panels are also used frequently in office space echo reduction.

- Damping: Think of damping as the silencer in your soundproofing toolkit. This involves the use of soundproofing materials like viscoelastic compounds and MLV to reduce vibrations and dampen impact noise.

- Decoupling: This involves the separation of building elements to minimize the transfer of vibrations. Resilient channels and isolation clips are often used for this.

- Distance: Sound waves spread out with distance, naturally lowering their intensity. Although less directly controllable, understanding how distance affects your needs can inform your overall approach to soundproof a room.

- Mass: Here, dense materials like MLV and QuietRock are used to stop sound waves from exiting a room.

- Sealing: In the context of how to soundproof a room, sealing is about using soundproofing materials like acoustic caulk and weather stripping to seal any gaps that could allow sound to leak in or out.

The Comprehensive Approach to How to Soundproof a Room

From selecting top-tier soundproofing materials to understanding the six elements, including the often-overlooked aspect of sealing, the goal is to take a comprehensive approach. Soundproofing is as much an art as it is a science, requiring not only the right materials but also a well-thought-out strategy. It’s a layered process—each element, from Absorption to Sealing, contributes to the ultimate goal of a quieter space.

As you consider how to sound proof a room, remember that different spaces have unique needs. Whether it’s absorbing sound in a busy office or damping vibrations in a home theater, knowing your specific requirements is essential. Tailoring your methods and material choices to these needs will set you on the right path. And remember: a well-sealed room is the foundation of effective soundproofing.

In Conclusion

In today’s hustle, the need to know how to soundproof a room cannot be overstated. With a range of cutting-edge soundproofing materials and techniques at your disposal, achieving a quieter space is more achievable than ever.